Cavendish Pianos - a new era for British piano makers

“I’m sorry we do not have such a thing as an English Piano”.

These are the words Adam and Charlie Cox, a husband and wife team

running Yorkshire Pianos, found themselves saying to many of their

customers looking for a new piano.

“People grew up with British pianos at school and at home and we find

that when people come to buy their own piano they are often looking

for that mellow sound that they grew up with”, says Charlie.

When the Kemble factory closed in Milton Keynes a few years ago, it

sounded the death knell for British pianos making. It was the last

remaining factory and when the gates closed for the final time skilled

workers, some of whom had been involved in the piano industry all

their lives, found themselves with nowhere to turn.

“We felt we had no choice but to either lose British Piano

manufacturing forever, or try to resurrect the art of making pianos in

Britain” says Adam.

Having traded for 15 years in Leeds as Headingley Pianos, the team

searched for new premises to not only act as showroom, but also as

piano manufacturing base. They looked at shops, industrial units,

church-halls… even a church! After well over a year’s searching they

had almost given up looking.

“Then one day I was on a bike ride to Bolton Abbey” says Adam “I knew

immediately it was the right place for us as I peered through a window

and saw a large barn of a room. What an acoustic I thought!”

Of course when they took it on it is was more like barn than a piano

showroom and workshop but with the use of a bank loan and the help of

local Wharfedale firms they were able to transform it and it is now

perfect for their needs.

“Lots of people ask if it was originally a church or chapel” says John

Spencer, head technician, “reclaimed ecclesiastical panelling and

doors were used in the conversion but it was built originally as a

forge.” Situated just off the busy A59 at the foot of Beamsley Beacon

with wonderful views in all directions it’s certainly an inspiring

place to work.

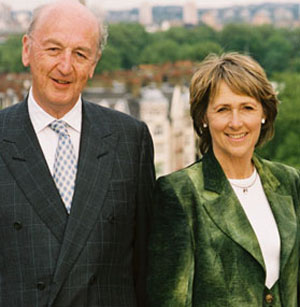

The Duke and Duchess of Devonshire paid them a visit early on and were

interested and then excited at the prospect of a piano shop and

manufacturing base on their estate at Bolton Abbey.

“They have backed our project every step of the way so we felt

‘Cavendish’ was the perfect name for our pianos, being the Duke and

Duchess’ family name. Without their kind patronage none of this would

have been possible”, says Charlie.

“We often talk in orchestral terms when describing piano sound. We are

looking for woodwind with undertones of strings rather than brass.”

“Price-wise things are starting to go full circle” says Charlie. The

days of cheap far Eastern pianos are ending as their manufacturing

costs are steadily going up (some Chinese pianos have almost doubled

in cost in the last few years) and shipping prices are soaring. We

find ourselves in the position where British goods actually can

compete with far eastern goods in the UK.

“Unlike microwave ovens, pianos are one of those things that are

better used in their country of origin” says Adam “They are very

susceptible to climate changes. After all, you have to remember they

are a complicated wooden machine which has been made in the same way

for a hundred years."

They have already had interest from many quarters and are just

managing to keep up with orders at the moment. Cavendish pianos are

even being well received in China explains Adam, "we exhibited at the

enormous Shanghai Music Fair last year which was a real eye-opener.

There is such a great appetite for quality pianos in China." Export to

China now makes up a large part of Cavendish sales.

"We have been involved with pianos all our working lives - they

are just such beautiful things! We feel proud to be making them"

say Adam and Charlie. It seems to me they have a right to feel

proud producing pianos in Yorkshire using not just traditional

skills, but love.

There is no shortage of skilled workers in the

piano industry and allied trades in this country. In fact, many

components are still made here and exported all over the globe for

piano making abroad.

“We felt it was crazy that British expertise was being used to make

the highest quality components for the piano industry and yet no

finished products were being made in this country” says Adam. For

example, Hainsworth in Leeds produce cloth and felt used in the

manufacture of many German pianos such as Steinway.

“Their quality is second to none and they’re on our doorstep while

people are buying pianos manufactured in the Far East!”

As one of the oldest companies in the UK (established 1783) Hainsworth

certainly know what they’re doing when it comes to textiles and their

knowhow and heritage is legendary in the piano trade. It's no

coincidence that one of the leading woollen mills should be in Leeds,

famous throughout the world for its history of textile production. It

was however coincidental that their wood source, British Hardwoods,

should be based in the Yorkshire Dales.

Also their supplier of wood finishes is near the traditional cabinet

making town of Thirsk. Silchrome Plating in Leeds, founded in 1949,

work in everything from aerospace to classic cars. Cox says "We

quickly started to realise we were not making ‘British pianos’ but

‘Yorkshire Pianos’.

“We were not using Yorkshire firms as a gimmick or because we liked

the idea but simply because they are the best in their field.”

Surrounded by pianos in various states of construction, John Spencer,

head technician at Yorkshire Pianos, sits down at a newly finished

Cavendish piano. “Of course the sound is the important thing” says

Spencer. “We are looking for that rounded, European tone that is part

of British piano heritage.” Spencer plays a smooth sounding chord then

moves over to a well known Far Eastern made piano and does the same.

The difference is staggering!

The Cavendish team

The team with Jamie Cullum

Adam Cox

Managing Director

Charlotte & Adam are partners in the family firm which began in 1990 as Headingley Pianos and later moved out of Leeds to become Yorkshire Pianos. With over 20 years experience in the piano trade they have always wanted to build pianos and in many ways this is the realisation of a dream.

Chris Foxton

Head Cabinet Maker

Chris is a skilled cabinetmaker based in Otley, West Yorkshire. He has a lifetime's experience working in fine woods and veneers.

Adam Connolly

Workshop Manager

Adam Connolly joined us in 2010 and rose through the ranks from lowly apprentice to workshop manager. Adam overseas all building processes with his watchful eye..

Emmanuel Vass BMus(Hons), CT ABRSM, DipABRSM

Piano Consultant

Emmanuel is an up and coming young concert pianist named as Yamaha's artist of the month. He has helped develop the Cavendish piano sound and is well aware of the needs of performing artists.

Mike Derrett

Head Technician

Mike joined the team in 2017 after graduating in piano technology at Newark. A highly skilled piano builder, Mike is responsible for action building on all Cavendish pianos.

Pippa Cox

Piano Tuner and Technician

Our middle daughter, Pippa, is a piano tuner both in house and looking after Cavendish pianos post-sale in customers' homes. A skilled stringer and piano technician.

Mark Challinor

Mark began building pianos with Laurence and Nash in the 1980s. Mark is also a well-respected guitar restorer. He works on soundboards and bridges.

Daisy Cox

Daisy Cox, our eldest daughter works in the office and looks after the websites designing and updating.

Charlie Cox

Financial Director

David Wilson

Piano Designer

Originally educated as a design engineer

with 15 years experience, David turned a life-long interest in

furniture making into a new career in 2003 after training at Leeds

College of Art and Design. Well grounded in traditional and modern

furniture making materials and techniques, David's passion is for

applying a clean-lined engineering approach to his designs while still

creating superbly crafted furniture, always without compromise.

Dovetailors

Felix Dombay-Walker

Apprentice Piano Maker

Felix Dombay-Walker joined us in 2018 as an apprentice piano maker. He has quickly learned the trade and is responsible for a range of jobs from prepping keys and action to regulation work.

Ken Forrest

Ken Forrest, one-time president of the Piano Tuners Association, works with us fly-finishing pianos and preparing pianos prior to dispatch.

Cavendish Pianos is proud to be making in Britain

Tradition

There is a tradition of piano making in Britain which stretches back over 200 years. Many of history's greatest composers owned and played British pianos; Chopin, Liszt, J.C. Bach among many others. In "The golden age of piano making" Britain boasted 360 piano makers at the turn of the century which supplied the entire globe. Sadly, this great industry has now all but disappeared from our shores. Notably in April 2003 The British Piano Manufacturing Co. and in October 2009 Kemble Pianos closed their gates for the last time.

Craftsman's Co-operative

Award winning Cavendish Pianos, based in

Yorkshire, are resurrecting the lost art of piano making in Britain

through the creation of a Craftsman's Co-operative. Piano Builders,

Action specialists, Stringers, Cabinet-makers, Polishers, and

PianoTuners all exist in this country.

Through the Craftsman's Co-operative these skills have been pooled

together to create a single finished product. Thus, rather than being

produced in one factory, Cavendish Pianos are made by a series of

small businesses each with their own speciality. This promotes a

higher degree of efficiency, less waste and more integrity and pride

in each individual aspect of the piano's make-up.

Craftsmanship-based small businesses in the UK are often finding

themselves marginalized by mass-produced imported goods. Cavendish

Pianos supports home-grown business and believes such firms can be

competitive, have a part to play and a real future.

Many components also continue to be made in this country. British

felts and cloths are widely regarded as the worlds finest.

String-makers still exist who have learned the specialized skill of

hand winding piano strings have practised all their lives. British

oak, ash and walnut is used for components and cabinets. A high grade

hammer and British made strings and design give Cavendish Pianos their

distinctive classic, European tone. This is a far cry from the harsh

Japanese tone of many mass-produced pianos. In many ways taste in tone

has gone full circle as we see a tendency for people to prefer a more

mellow, sweeter, traditional sound.

Our Patrons

Our patrons, the Duke and Duchess of Devonshire (Cavendish) have a long illustrious history as patrons of the arts, and music in particular.

The building of Cavendish Pianos takes place on the beautiful Bolton Abbey Estate.

We are indebted to them for their continued support.

The Cavendish partners

The Piano College

Cavendish Pianos is partnering with The Piano

School at Lincoln College. The Piano school is the last remaining

place where piano technology is taught in Britain. We believe it is

vitally important to keep piano making skills alive in the UK

British Hardwoods

The first oak log was converted at Lotherton

Hall in the Vale of York in 1993. Using a mobile chainsaw mill

purchased with the help of a £3000 loan, Joiner and Wood Machinist

Tony Fillingham gradually built-up a stock of mature hardwoods from

fallen and inaccessible logs. In 1994 the first kiln was commissioned

drying 250 cu. ft. per month. This was closely followed by the

installation of timber processing machinery.

British Hardwoods has moved premises three times since then and now

operates from its own 14500 ft² purpose built factory on the edge of

the Yorkshire Dales.

Brimming with state of the art machinery and quality kiln dried

hardwoods, the unit also boasts superb offices, showrooms, a trade

counter and shop. The entire building is heated with an eco-friendly

system utilising waste shavings and all timber used, comes from

sustainable resources. British Hardwoods also has excellent

environmental credentials.

Renner Hammers

Louis Renner began on a very modest level with

the production of piano mechanism in October of 1882. Renner today is

the largest, independent purely action manufacturer for upright and

grand pianos in the world. The company's success is due to their

ability to produce custom made actions for the individual customer.

Apart from Schimmel, Renner mechanisms are exclusively used by such

reputable companies as Steinway & Sons in Hamburg, Fazioli/Italy,

Bösendorfer/Austria, Grotrian-Steinweg, Bechstein Ibach, Feurich,

Seiler, Sauter, Steingräber & Söhne, Pfeiffer, Leipziger

Pianofortefabrik, Zimmermann, Steinberg, Blüthner, and Förster. In

other words, all the German piano manufacturers. Moreover, Renner can

count other reputable European piano manufacturers among their

customers, such as Rameau, Generalmusic, Petrof, ERA Seidl, Calisia,

Legnica, and in Asia such famous companies as Daewoo, Samick, Young

Chang, Kawai as well as all well-known companies on the American

market such as Baldwin, Charles Walter, and Mason & Hamlin.

Making use of the latest know-how in the application of computers and

electronic controls, superior quality is produced, as the former

premier of Baden-Württemberg, Dr. Lothar Späth, said: "Quality is

honesty in action" or as a Swabian put it: "Quality, that's a matter

of decency."

Hainsworth Textiles

With over 30 years of proven experience

Hainsworth partner the most prestigious names in the piano market

including Steinway and Renner. Our pure new wool woven cloths provide

excellent shape retention and durability. Our ISO9000 standing and

strict quality control throughout the production process enables

manufacture to the tightest tolerances.

The cloths are designed specifically to fulfil their unique part

within the piano – from the smooth movement of the pin to the ultimate

cushioning of the hammer. As the world leader Hainsworth can adapt our

proven quality cloths to conform to customers own manufacturing

specifications. Our constant aim is to give our customers consistency

and stability of product to allow for the most effective smooth and

quiet use of the cloth within the piano. Our fully equipped in-house

conversion facility allows us complete flexibility in providing

tailored products sizes to our customers' end uses– offering the full

range of washer and strip sizes.

Pianostrings

Piano strings are hand spun by Barney Unwin

and can be supplied for grand pianos of all sizes and for all upright

pianos.

Fitting piano strings is a skilled job and should be carried out by an

experienced piano tuner or piano technician. Each piano string,

whether made individually or as part of a set of piano strings, is

made to order so you can be sure that your piano strings will fit your

piano perfectly.

Piano strings hand spun by Barney Unwin are competitively priced and

are shipped worldwide including the UK, the USA and Europe.

Barry Caradine

Polishers

Unrivalled expertise and vast experience combine to provide the most

complete and versatile pianocraft service on offer. Barry and Roberta

can restore the most worn-out and mistreated instruments to original

condition. For a new lease of life for your instrument, contact Barry

Caradine. You'll find it's music to your ears.

Barry started his piano restoration and refurbishing business after a

career with Bösendorfer as a concert technichian in the UK. He

qualified after training under Malcolm McKeand, at the London college

of furniture. Carradine bought up equipment from the Kemble factory on

its closure in the UK which is used to make parts for Cavendish

pianos.

Delta Adhesives

Our company success is based upon a commitment

to first class products and service with the customer at the centre of

everything we do.

Our high quality products remain at the core of our business and

continuous development, including Worldwide exports, combined with

excellent technical service has ensured Delta Adhesives retains a

leading position in a competitive market.

The adhesive market is constantly evolving, Delta Adhesives record of

developing products that give excellent results on the most difficult

materials, will ensure that customers can continue to specify our

grades with confidence that their needs will be met.

Rydenor Wood Finishes

Established in the North Yorkshire village of

Sowerby near Thirsk in 1965, Rydenor Products was acquired by Geoff

and Anne Etherington in 1980 and moved seven miles south to the

village of Hutton Sessay.

The company has expanded and developed in that time constantly

broadening and upgrading its wood care product range.

A move from the buildings in Geoff's backyard to a purpose-built

commercial unit between Dalton and Topcliffe in 1992 further enhanced

the company's ability to serve its customers. Geoff's son Roger joined

in 1989 and now runs the company.

Rydenor's wood care product range is vast, from it's own 'Waxwing'

range of waxes and French polishes, through to many other products

found in the restorer's workshop, to lacquers, stains and waxes from

the leading manufacturers.

H.J.Fletcher & Newman

Supplying Piano Parts to Piano Tuners,

Manufactures, Technicians, Schools, Colleges and Universities all

round the world for over 124 years with:

Action Leather, Action Parts, Tools, Springs, Strings, Legs, Music

Desks, Castors, Keys, Key covering, Tuning forks, Damper felt, Felt,

Baize, Wire Cutters, Regulating Tools, Hammers, Piano Tuning Tools

and many more items......

Henry Shaw & Sons

Henry Shaw & Sons Ltd has always been a

family firm. Founded by Henry Shaw in 1799, the company was initially

set up as a manufacturer of wrought nails, rivets and chains. Henry

bought a house in Park Street, Birmingham from a Mr Lloyd (later of

Lloyd's bank fame) and leased two warehouses from Great Western

Railways.

And the rest, as they say, is history.

Now in its third century of continuous service, Henry Shaw & Sons

Ltd has become one of the UK's largest trade suppliers of woodscrews,

fixings and fastenings, nails, bolts ironmongery and fencing products.

Dickens Brothers Ltd

Dickens Brothers Ltd is a small family

company, which has been producing leather since 1897. The founder of

Dickens Brothers, William John Dickens was born in 1860, the son of a

village shoemaker.

John Dickens (his preferred choice of name) spent all of his early

working years in various leather related trades before deciding to set

up his own business in 1897. Two years later he decided that new

premises were necessary and acquired land to have a purpose built

factory situated in Kettering Road Northampton. This was completed in

1900 and this where we still produce leather today.

During a century which has seen many industrial disputes in the wider

economy, Dickens Brothers was hardly affected. In fact in the general

strike of 1926 just a handful of days was lost.

At least ten Dickens Brothers employees clocked up more than 50 years

service during the century of existence. The spirit of the company has

always been that the directors worked along side the employees and

today Brian Dickens can be seen in the warehouse amongst bales of

rough leather and horses of finished leather.

Thomas Flinn & Co

At Thomas Flinn & Co., we have been

providing high quality saws all over the world since 1923. Many of our

brands have history dating back into the 18th century and are well

recognised as the sign of quality in saw making. Our brands include:

PAX, Lynx (The Garlick Saw Company) and more recently, the Dorchester

and Parkstone brands which originate from Roberts & Lee Saws. We

are proud to be standing as the UK's only remaining traditional saw

manufacturer. We pride ourselves on having a skilled combination of

modern technology and traditional hand craftsmanship associated with

only the finest saw manufacturing. We intend to provide only the

highest quality products which will last you a lifetime with care. Our

retail website enables us to continue our company ethos further, where

we aim to promote high quality, Sheffield made tools. Many of these

tools are also made by independently owned companies, which like

ourselves have lengthy history and generations of craftsman still

making these tools. It is through customer appreciation and support

that this tradition can continue into the 21st century.

Early Keyboard Agency

EKA or Early Keyboard Agency is a family run

business based in Oxford in the UK.

EKA specialise in the manufacture, sale and distribution of piano bass

strings as well as the restoration of Square Pianos, Harpsichords,

Spinets and Clavichords.

Dovetailors

Dovetailors cabinet makers produce made to

measure furniture and kitchens-furniture designs that are literally

tailor-made around you.

You give us an idea, and we make it by hand into something truly

bespoke. And if you don’t have an idea of what you’re looking for,

don’t worry, we can work it out together. We’re also quite handy at

creating designs that you’ll love before we even lift a chisel.

What makes us unique is that we hand-make furniture you won’t see

anywhere else, except maybe in your head. So for bespoke kitchens and

fitted furniture that’s made to your measure, you’ve come to the right

place. Everybody fits in around here.

![]()

Silchrome Plating

Silchrome Plating Ltd is a privately owned

company established in 1949 and offers a wide range of metal finishes

to a variety of industries.

These include:- Aerospace, Defence Industries, General and Precision

Engineers, Shop Fitters, Plumbers Merchants, Jewellers, Antique

Dealers, Classic Car and Motor Cycle Restorers to name a few.

Over the years the Company has received many customer and industry

approvals.

All processes are rigorously controlled to ensure all coatings and

finishes confirm with the relevant British Standards, Defence

Standards, American Military Standards or customer specific process

specifications.

Gabor Silent Pianos

The Gabor System is really a simple idea,

which can allow you to practice on your acoustic piano at any time at

all.

With a touch of a leaver you can stop the piano hammerheads short of

hitting the strings, so you can practice on your piano without

disturbing your neighbours or your dad who is watching football on the

television in the same room as the piano. Just put the headphone on

and play on your piano, and keep the music to yourself.

The Gabor System will take your acoustic musical instrument into

another dimension of the electrical world. This simple marriage of

acoustic with electric works very well, it allows you to play on your

acoustic piano and can sound like a Cathedral Pipe Organ, a string

quartet or anything you want it to sound like. The Gabor System

enables you to connect direct into your computer and record your

composition into your PC, and use it as a recording studio.

Heckscher & Co.

Heckscher & Company was established in

1883 by Siegmund Heckscher who had recently arrived in London from

Hamburg. The company moved to its existing Bayham Street premises

shortly afterwards.

Siegmund was succeeded by his son Leo, who ran the company until his

death in 1958. He had been assisted by his sons Derek and Roy, who

continued until their retirement in 1984. Martin Heckscher, Roy's son,

joined the company in 1971 and continues the family tradition as the

current Managing Director.

Since 1883 it has been our aim to provide all our customers in the

piano trade with the best possible service. That aim is as keen today

as it was then.

Tenniswoods Removals

Tenniswoods Removals Service

The right move.....

All Types Of Removals. Specialist Ombudsman approved scheme

guaranteeing quality service value & integrity by a vetted

removals company. Call us & ask for more comprehensive

information.

Our Experienced staff offer a high quality service including

specialist for piano's, antiques, paintings etc including full packing

if required.

*Local, National & International

*Full & Part Loads

*Complete Packing Service

*Packing Cases & Garment Cartons

*Expert Service Guaranteed.

Essex Hinge Co

We have more than 70 years experience plus the

design expertise and manufacturing capability to produce custom hinges

for demanding applications.

The high cost of initial tooling has been the drawback to producing

custom hinges by traditional methods. We have invested in state of the

art manufacturing equipment which overcomes this problem. This means

that high quality custom hinges can be produced quickly with minimum,

and in some cases, no tooling costs.

Our highly skilled team with state of the art manufacturing methods,

produce quality hinges you can rely on.

Smith and Allan

One of the UK's largest independent lubricant

manufacturers. The production of Smith and Allan lubricants dates back

to 1925, the intervening years have seen us forge strong and lasting

relationships with the world's largest additive manufacturers and in

particular with Shell Oils.

Anita Marquetry

Anita Lear Sancha MA RCA, Welsh Business Woman

of the Year 1999, formed Anita Marquetry in 1991 having developed a

passion for marquetry. The well established team of professional arts

graduates in our design studio are highly qualified, competent,

innovative and enthusiastic. They love their work and you will love

working with them. From initial contact the team will work alongside

the client giving advice on design, materials and techniques to ensure

the accurate interpretation of the concept. The combination of skilled

craftsmanship with modern technologies means that we can complete the

most complex projects in weeks rather than months. Our clients return

time and time again - a testament to our quality and service.